We have reached number 2 of the top 5 most cited fall protection violations list of 2016. Just like we did earlier in part 3 (roofing work on low-slope roofs), part 4 (Steep roofs) and part 5 (Holes and Skylights), we will provide insights in the OSHA standard and advice on how to prevent dangerous situations regarding that standard.

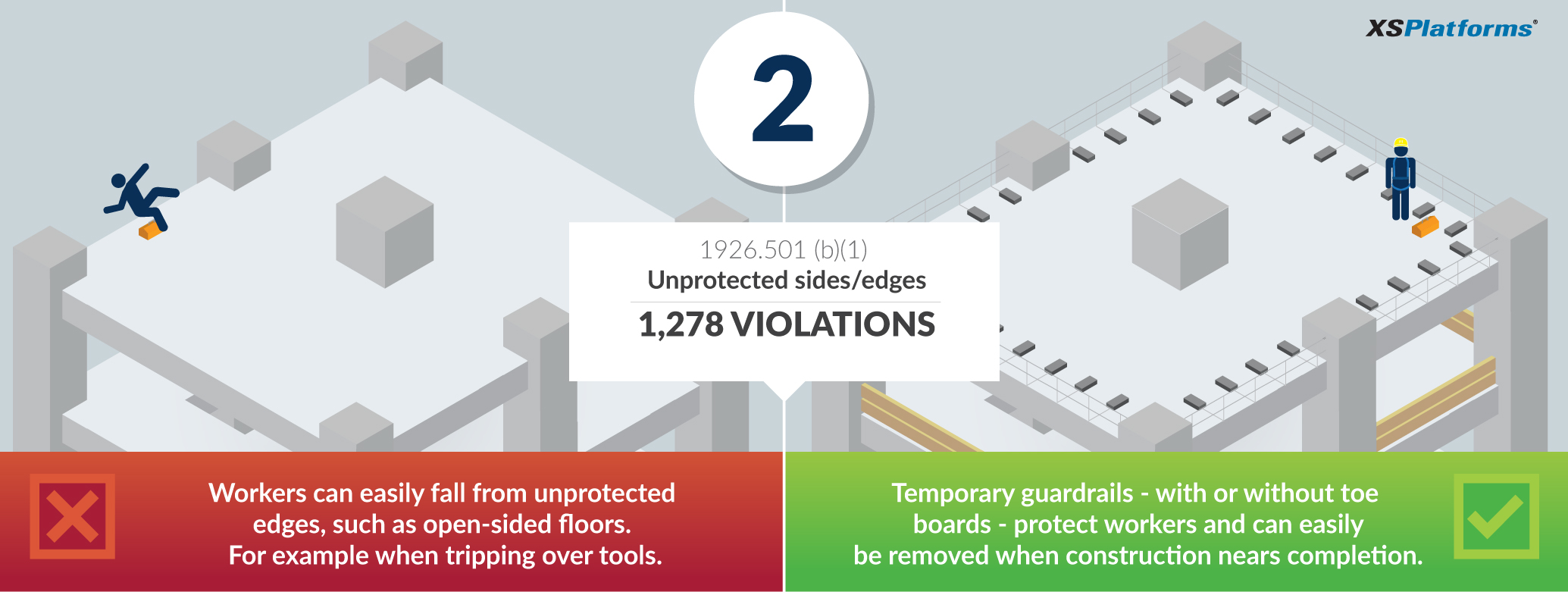

The number 2 most cited violation within the OSHA fall protection standard is:

Subpart 1926.501(b)(1) Unprotected sides and edges

“Each employee on a walking/working surface (horizontal and vertical surface) with an unprotected side or edge which is 6 feet (1.8 m) or more above a lower level shall be protected from falling by the use of guardrail systems, safety net systems, or personal fall arrest systems.”

In 2016, this standard was cited 1,278 times. This is more than twice as much as the number 3 on this list, ‘roofing work on low-slope roofs’, which is exactly the reason why the right safety measures have to be taken when working on a floor or roof with unprotected sides and edges.

What does this standard mean?

This standard applies to horizontal and vertical working areas that are 6 feet (1.8 m) or higher above a lower level. This can be a roof, but also an unfinished concrete level of a tall building, a protruding platform or another surface. On top of that, the edges of the walking/working area are not protected by a physical barrier (wall or guardrail) of at least 39 inches (1.0 m) high to be labeled as ‘unprotected’.

Fall hazards

Obviously, a walking/working surface with unprotected sides and edges entails safety risks. Workers can lose their balance, trip over tools or debris, slip on a wet surface or another cause that could result in a fall over the edge.

To prevent serious injuries, or worse, this OSHA standard provides various solutions to prevent workers falling from height: (temporary) guardrail systems, safety net systems and personal fall arrest systems.

Safety measures to prevent falls from height

(Temporary) guardrail systems

Placing a guardrail system along the edge will make sure workers can’t fall off the walking/working surface. According to OSHA standards, the top edge of the top rails needs to be at 42 inches (1.1 m) above walking/working level (with a margin of 3 inches (8 cm).

Guardrails can be temporarily or permanently placed alongside the edge of a walking/working surface, so workers can always work safely. These guardrails can be permanently placed, so workers can always work safely. A disadvantage of permanently placed guardrails is that the guardrails are always visible, so when installed on a roof for example, this might affect the building’s design. Another option is installing a temporary guardrail system that can be assembled when work at height has to be done and disassembled when it’s not needed any more. A drawback of a temporary system is that it takes up valuable time to assemble and disassemble the guardrail system. Temporary systems are often used when occasional work is performed or when a working platform is partly done and side/edge protection will be installed later. Another option could be foldable guardrails. These are permanently placed, but can be folded down when work (on a roof for example) is done. When folded down, the guardrail system is out of sight.

Safety net systems

Often used on high-rise buildings during construction, like described in part 2 and part 3 of this series. This solution stops a fall after a worker has fallen over an unprotected edge. The biggest drawback of a safety net system (or ‘netting’) is that it can be installed up to 30 feet (9.1 m) below the walking/working surface. When falling into a safety net from that height, workers can still sustain injuries. On the other hand, it does stop the fall and worse injuries are prevented.

Personal fall arrest systems

The third safety measure provided by OSHA is the use of a personal fall arrest system. This solution is not a physical barrier, like a guardrail system, but it limits a potential fall to a minimum (using a fall arrest system) or prevents a fall from happening at all (using a fall restraint system).

For a personal fall arrest system, three elements need to be present. First, an anchor point needs to be installed on the walking/working surface. This can be a permanent anchor point, like a single anchor point or a lifeline system. Also a temporary anchor point can be used, like a temporary lifeline, stretched between two single anchor points, a deadweight anchor point or a sling.

Second, a lanyard has to be used with a Personal Energy Absorber to attach the worker to the anchor point. The energy absorber is required to limit the stopping forces on the body when a fall occurs, also referred to as Maximum Arrest Force (MAF). This will prevent (serious) injuries.

Third, the user needs to wear a full-body harness to attach the lanyard to. The type of harness required is determined by the placement and the number of attachment points on the harness, combined with the choses fall protection solution.

For example, when work on a pitched roof needs to be performed and a horizontal lifeline runs along the roof top, the lanyard needs to be attached on the chest. A harness with an attachment point on the chest will be required in that situation.

The biggest advantages of this system are the minimal impact on a building’s design and the elimination of the risk of falling when the system is used properly. A drawback is that the user needs to know how the system is used properly and training is required.

Choosing the right fall protection system

Because unprotected sides and edges are encountered often when work at height needs to be performed, the solution that best fits the situation varies. For example, on a high-rise construction site where workers work on a concrete floor, a temporary guardrail system could be the preferred solution. But when workers often have to access a roof for maintenance, permanent guardrails or a personal fall arrest system can be used.

Always assess the specific situation on a job site and take appropriate safety measures to protect workers on working platforms with unprotected sides and edges from fall hazards.

Top 5 section violations infographic

We have summed up the top 5 most cited violations of the OSHA fall protections standards in an infographic. We also provide advice on how to create a safe working environment at height and comply to the OSHA standards.

Download the infographic, share with your co-workers and use it to make sure nobody is unnecessarily exposed to fall hazards.

1 Comment. Leave new

Thanks for pointing out that the top of guardrail systems need to be at least 42 inches above the working surface to meet OSHA standards. My brother wants to have some removable guardrails installed on his commercial property to keep the workers safe during his construction project next year. The info you shared here should be helpful as he starts working with a guardrail installation service!