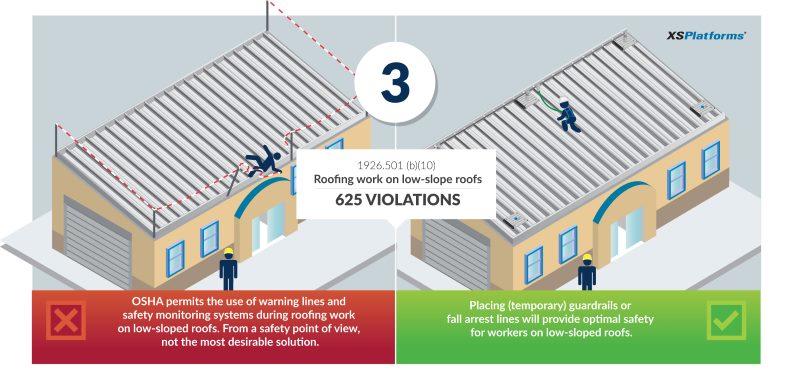

After describing number 4 (Steep roofs) and 5 (Holes and Skylights) of OSHA’s most cited violations in 2016 and providing advice on how to prevent unsafe situations, we now take a look at number 3 on the list:

1926.501(b)10 Roofing work on low-slope roofs

‘Each employee engaged in roofing activities on low-slope roofs, with unprotected sides and edges 6 feet (1.8 m) or more above lower levels shall be protected from falling by guardrail systems, safety net systems, personal fall arrest systems, or a combination of warning line system and guardrail system, warning line system and safety net system, or warning line system and personal fall arrest system, or warning line system and safety monitoring system. Or, on roofs 50-feet (15.25 m) or less in width, the use of a safety monitoring system alone (i.e. without the warning line system) is permitted.’

This section was cited 625 times in 2016. In comparison with 2015 when this standard came in fourth, this is a decrease of 13%.

Explanation of the standard

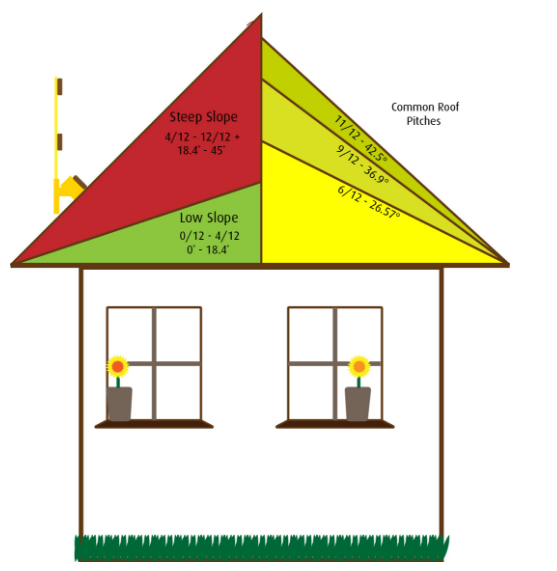

In our previous article about citations regarding the standard for steep roofs, we pointed out that OSHA standard 1926.500 defines a steep roof as a roof that has a pitch of 18,5° or more.

According to this definition, a low-slope roof has a pitch of less than 18,5°. The difference between steep and low-slope roofs is depicted in the image below.

What are the risks on a low-slope roof?

The first thing to do when work on a slanted roof needs to be done is to assess whether the roof is steep or low-sloped, based on the definition by OSHA.

Second, appropriate safety measures need to be taken to provide a safe working area. In case of a low-slope roof with unprotected sides and edges, these might SEEM unnecessary because the perceived risk is low. Nevertheless, the risk of falling is always present!

Safety measures for working on a low-slope roof

Equipping the roof with a (temporary) guardrail system along all the open sides and edges will result in the whole roof being a safe zone. A potential fall will be stopped by the guardrails. In contrast to the guardrail system on a steep roof, guardrails on a low-slope roof don’t have to be equipped with toeboards.

The downside of this solution is that the aesthetics of a building are affected. Placing temporary guardrails might be an option. But take into account the extra time and costs for installing/uninstalling the system every time it has to be used.

Safety net system

As described in the article about Steep Roofs (OSHA violation 4), this solution will mostly be used on higher buildings during construction. A net (or ‘netting’) is installed as close to the building as possible in order to prevent workers from falling down.

Apart from affecting the aesthetics of a building, this solution has another big disadvantage: the net may be placed 25 to 30 feet below the working area. This means that workers still fall that distance before the fall is stopped. An unwanted situation from safety point of view, because serious injuries might still be caused.

Fall arrest system

Another option to consider for safe working on a low-slope roof is a (temporary or permanent) fall arrest system. This solution prevents a person from falling by restraint to an anchor point that is installed on the building. The user has to wear a harness and connects himself to the anchor point, using a lanyard.

The advantages of this solution are that the aesthetic value of the building is minimally or not affected and the risk of falling is eliminated when the system is used properly.

The difference between safety measures

So far, the measures described to work safely at height are similar for steep roofs and low-slope roofs. We will describe another safety measure below that is permitted by OSHA for working on low-slope roofs.

Monitoring system

According to OSHA, a monitoring system can be used in combination with the solutions provided above. This means a competent person monitors the worker(s) on a low-slope roof. That person needs to be on the same walking/working surface and warns the worker(s) when fall hazards are observed.

In combination with a guardrail system, safety net system or a fall arrest system, a monitoring system is a good addition to increase safety. But, there is one other combination of safety measures that is allowed by OSHA for safe work on a low-slope roof: a monitoring system combined with a warning line.

A warning line is a line made of ropes, wires, chains or another barricade equivalent in strength (minimum of 500 lbs / 227 kg tensioning strength). This line is not designed to prevent a fall, but to indicate fall hazards only. So when a worker should fall near the edge of the roof or slides down, despite a potential warning from the monitoring person, the chances of falling off the roof are high.

On roofs under 50 feet (15,25 m) wide these chances are even higher, because only a monitoring system would be sufficient to comply to the OSHA standard.

Although these two safety measures are labeled as safe by OSHA, these aren’t the preferred solution, because chances of falling are still high. We would always advise to install a guardrail system or a fall arrest system to prevent falls and serious injuries when work is performed on a low-slope roof.

Top 5 section violations infographic

We have created an infographic based on the 5 most cited sections within the Fall Protection standard. In this infographic we have visualized the top 5 violations and provide solutions and advice on how to create safe working conditions in these situations and comply to the OSHA standards.

Want to receive the infographic? Subscribe and we will send it to you directly!