HOW TO CHOOSE

A FALL PROTECTION SYSTEM?

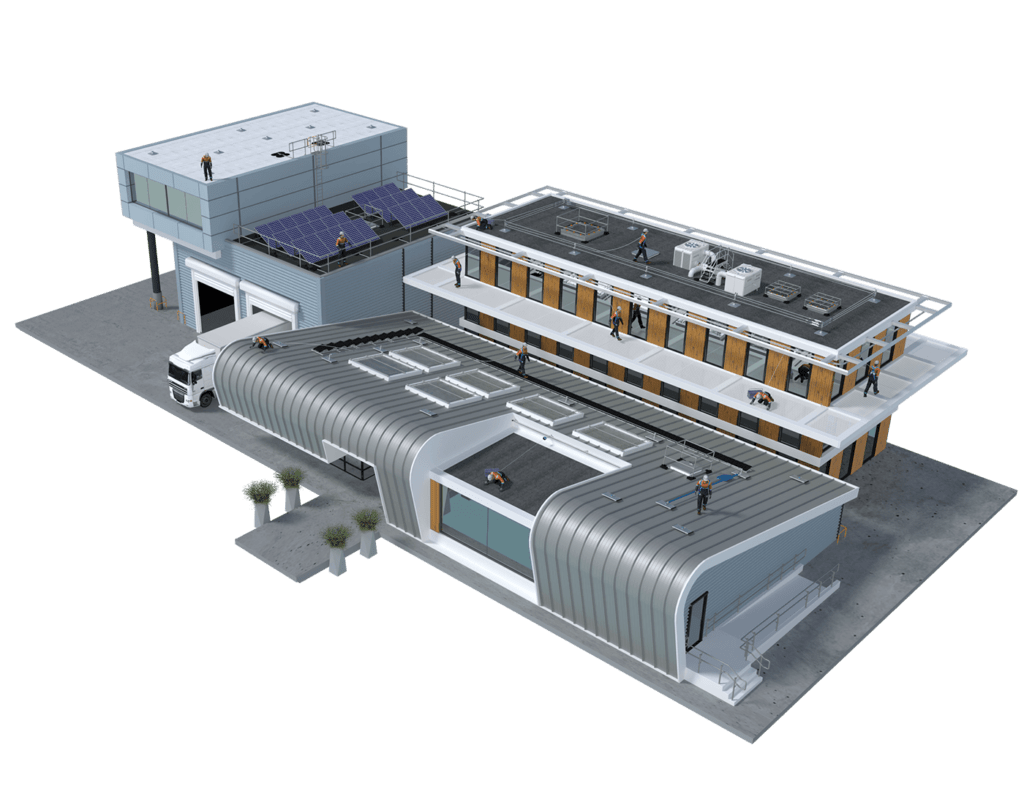

Our range of innovative fall protection solutions and personal protective equipment, offers absolute safety and superior usability to anyone working at height.

Our safety systems are available for any workplace at height. From working on roofs, to working inside factory locations. From working on masts, to working on a cruise ship. Our fall protection solutions come in a wide variety. And if you can’t find a solution in our range, we will custom engineer a suitable fall protection solution for you.

With the fall protection systems of XSPlatforms, the Fall Protection hierarchy can be applied using our Safety with a Star System.

With a gradation of safety stars, roof safety can be guaranteed in any form, for any situation at height.

To guaranty your safety, XSPlatforms Partners uses the ODIN Lifeline Calculation Tool. This tool helps to save time on complex calculations, and automatically generate detailed reports and prevent expensive miscalculation. With the use of ODIN you can setup and report lifeline compliance systems for the following standards:

Do you want to use ODIN in combination of selling our products? Join our Partner Program today or request a Demo at ODIN-tool.com!