In our previous blog – Ladders vs Scaffolds: part 1 – we looked at falls from heights statistics. We saw that scaffolding violations rank much higher than ladders in OSHA’s top 10 each year. But ladders account for a lot more actual accidents, both non-fatal and fatal. Today, we are going to take an in-depth look as to why that is, and how the number of accidents can be reduced.

Scaffold safety versus ladder safety

1. Training

It is our opinion that this contrast is explained by the higher number of untrained workers that have access to ladders. OSHA does not require workers using ladders to be trained. Employees erecting, moving, dismantling, or alternating a scaffold however, have to be properly experienced, trained and be selected by a competent person. Because ladders are mostly used for lower heights, users often have a false sense of safety. In fact, 59% of fall accidents occur at 20 feet or less.

2. Fall protection requirements

This brings us to the next significant difference. When comparing supported scaffolds with portable ladders and step ladders, we see a lot of differences in safety requirements. One of the most noticeable differences is the fall protection requirement. Scaffolding standards state that either a guardrail system or a personal fall arrest system (FAS) should be used when the scaffold is more than 10 feet high. However, OSHA standards do not require fall protection for portable ladders below 24 feet. But if two-thirds of all fall accidents occur from 20 feet or less, shouldn’t workers using ladders that high also be protected from falls?

It is our interpretation that the fall protection requirements are the most important difference between the two solutions. But there are more reasons why we believe scaffolding is safer than using portable or step ladders.

3. Height to base width ratio

To prevent them from tipping over, OSHA specified the maximum height of supported scaffolds before they have to be restrained. Supported scaffolds may reach four times the base width before restraints are required. So a 2 feet wide scaffold may reach 8 feet in height without using restraints. When outriggers are used, the same scaffold will have an even wider base so the same scaffold may reach higher without its stability being reduced.

Looking at step ladders, we do not see such a requirement. Although the height of step ladders is restricted to 20 feet (Type 1A Heavy Duty Industrial ladders), it is not defined by the smaller base dimension like we see in the scaffolding standards. This means a 2 feet wide step ladder may theoretically still reach 20 feet in height. This translates into a 1:10 ratio, rather than 1:4. In our opinion, this results in a very unstable and unsafe situation.

4. Working height and platform

OSHA states that “the top or the top step of a stepladder, shall not be used as a step”. Concluding that every rung between this and the base is potentially a work platform . This means you have a very limited working area, no larger than the dimension of the rung you are standing on.

Supported scaffolds on the other hand, have a clear working platform, assembled with either planks, prefabricated decks or platform modules. The result is a large working area, where you can easily stall tools and materials, have increased freedom of movement and can work safely in any direction.

5. Protective railing

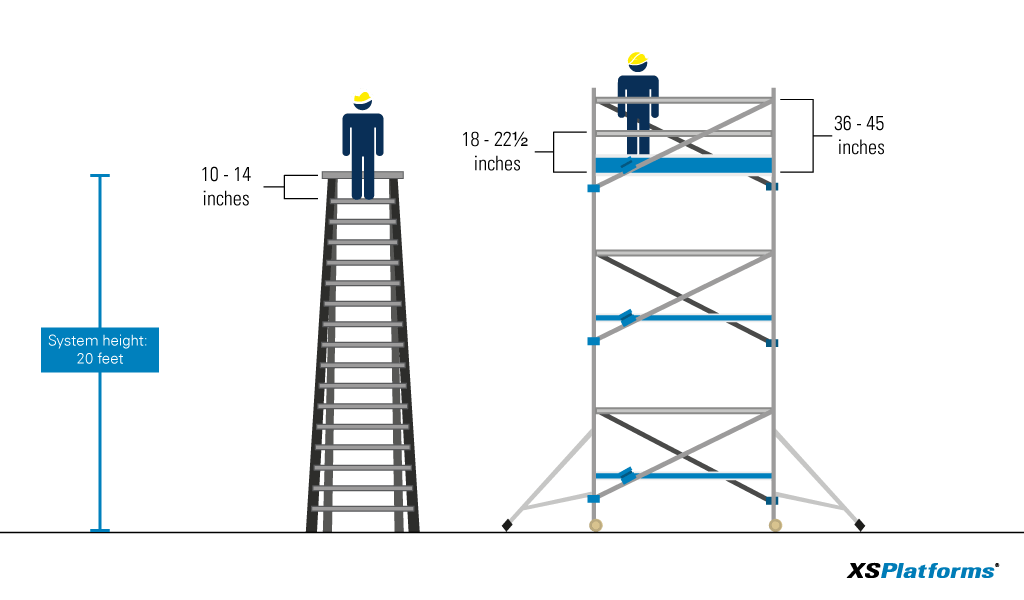

The situation mentioned above brings us to another noticeable difference. Because the top or top step may not be used as a step, you might interpret that it functions as a knee rail. However, with a maximum distance of 14 inch between rungs, it is not nearly as high, and safe, as a scaffold’s protective railing.

A guardrail system for scaffolds must have a toprail, with its top edge placed between 36 and 45 inches above the platform surface. The midrail has to be placed approximately midway between the top edge of the guardrail system and the platform surface. This translates into a distance between 18 and 22½ above the platform.

With not one but two guardrails, placed more near the hip of the user, a scaffold with a guardrail system will offer more fall protection than a ladder. Even when the top or top step is not used a step.

Safer work at height

We realize that in some situations, using a ladder is the most practical one. However, when it comes to safety, we recommend using a scaffold rather than a ladder or stepladder. Especially when one or more of the following is the case:

- The working height is 6 feet or higher.

- Freedom of movement is required.

- Tools and materials need to be stored at the needed working height.

- When you want to prevent, or reduce, worker fatigue.

- When more than one user need to work in the same area.

To receive all the statistics and pros and cons discussed in this blog series, please download our infographic.