Working at height requires the protection from fall hazards. When you cannot fully eliminate the fall hazard collective fall protection measures, such as guardrails, are the preferred solution. However, there are situations where this is not a viable option. Then a personal fall protection system can help keep workers safe in the form of either a work restraint or a fall arrest systems. For a personal fall protection system you’ll need some type of anchorage possibility for a worker to tie-off to.

One solution could be a system of single anchor points, another solution is a horizontal lifeline system (HLL). Both solutions need to be combined with a lanyard and a full body harness. In this blog we’d like to provide a comparison between these two systems and point out the advantages. We need to stress, however, that there is no one-size fits all solution to provide fall protection. Every situation has its own challenges and thus requires a different system to combat the site specific risks.

Using a single anchor point system for fall protection

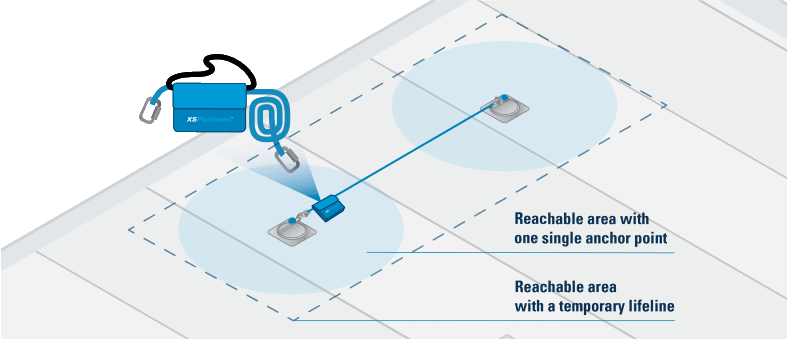

A system of single anchor points can be installed in the middle of the roof, or along the safe edge of the roof parameter depending on the shape and size of the roof surface. A worker needs to detach from one anchor point and reattach to another when they need to switch to a different work area.

Most single anchor points are only suited for use by one person at a time. Making it difficult for an entire team of workers to work simultaneously. A temporary lifeline, or anchor line, can be placed between two anchor points to allow multiple users to work together, or to allow more freedom of movement. Check the product’s details to see if this extra piece of equipment is suitable for multiple users.

Next to single anchor points for fall restraint and fall arrest, XSPlatforms also offers single anchor point solutions that allow users to perform rope access duties.

Using a horizontal lifeline system for fall protection

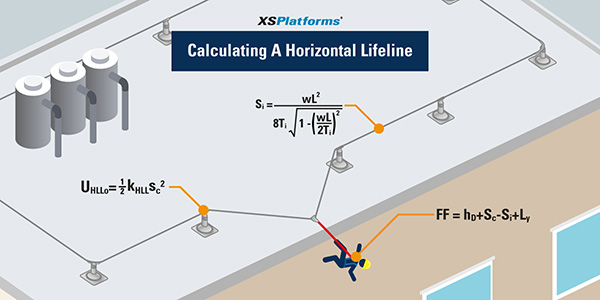

A horizontal lifeline system (HLL) consist of a series of anchor points that are connected via a steel wire-rope. Workers attach to the lifeline track and travel along the trajectory, without having to detach and re-attach.

You may also be interested in an earlier blog in which we made a comparison between a horizontal rail system and a lifeline system.

Horizontal lifelines can be configured in such a way that multiple users can work with one system at the same time. Making it easier for a team to work safely together. XSPlatforms has even developed a system with multiple lifelines, so that workers can pass each other without having to disconnect from the lifeline system. An XSPlatforms horizontal lifeline system can also be equipped with additional RAP anchor points to enable rope access from that location without harming the freedom of movement of the HLL users.

Freedom of movement for work execution

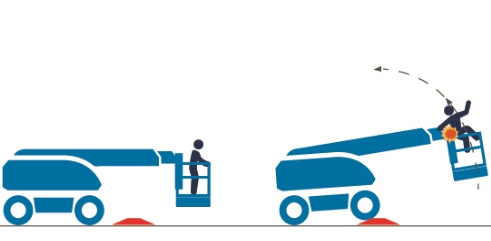

What system is most suitable for a project depends on a couple of factors, one factor is the work area that needs to be reached. Single anchor points, with a 360o rotation eye, allow movement in a circle around the anchor point. This could mean that certain areas, for example corners cannot be reached if the system is installed in the middle of a roof.

In order to reach all the rooftop areas more anchor points need to be installed. You can place anchor points near corners and edges but that could increase the risk of a fall, which is something you should prevent. Not to mention that if workers have a fixed length lanyard they will need proper fall clearance. Should a fall occur they should not be able to fall to a lower level. If an adjustable lanyard is used, workers must adjust the length accordingly to the distance to the roof edge.

A horizontal lifeline system can either be installed in the middle of the roof, or on the edge of the safe zone, following the contours of the roof. Workers can then travel along the lifeline, passing over the intermediate points and corners without disconnecting. This provides a larger range and greater freedom of movement.

Level of training

For working at height in general, and thus for both the single anchor point system and the horizontal lifeline system, workers need to be educated on proper use and safety measures. When workers use an adjustable lanyard they need to be instructed on the available fall clearance, so that they can always adjust their lanyard accordingly.

Additionally workers need to be instructed on how to inspect their personal safety equipment before use. When a defect or weakness is detected they need to report this to the building owner or site manager.

Replacements or repairs

A system involved in a fall arrest has most likely sustained damage and needs to be re-certified by a trained professional. Often parts of the system, or the entire system, have to be replaced. But not only arresting a fall can damage a fall protection system. Intensive use or operating in an industrial environment can also cause (unseen) deterioration. This is why all fall protection systems have to be inspected before every use by the user, and we advise to let it be inspected annually by a competent authority.

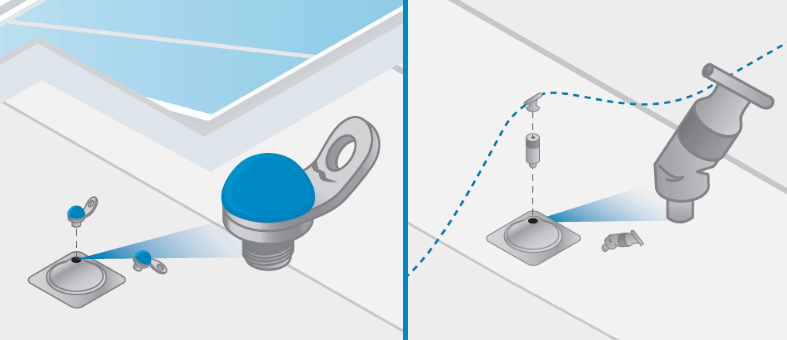

Damaged anchor points often need their safety eye replaced as this component can deform due to the impact of a fall. The base plate of an anchor has to be load tested after a fall arrest to ensure it is still safely mounted to the roof surface.

A horizontal lifeline on the other hand, has more components and thus has more parts that could need replacement. The wire rope could be damaged. For this there are two options available, removing and replacing the damaged part or replacing the entire system’s wire rope trajectory. Engineered lifeline trajectories have integrated energy absorbers, as these are activated when a fall occurs they will need to be replaced before the system can safely be used again. The anchorage points that connect the lifeline system also need to be checked (via an anchor load test) after a fall.

As you can read repairing a lifeline system after a fall means executing more actions than replacing an anchor point, costing more time.

Costs

A horizontal lifeline system is custom made to fit a specific project. Several calculations are made to ensure the system is compliant to local safety regulations and that enough fall clearance is available. As a lifeline system consists of more components this system requires a greater investment. However, ease of use and accessibility of the roof can be a reason why this system is a better fit.

The main goal is to prevent falls, and thus costly injuries, from happening. But, should a fall occur both systems ensure user safety.

Download infographic single anchor point vs HLL

Both systems offer the same amount of safety, when installed, maintained and used properly. There are situations when one may be more suitable than the other, but this differs per project.

Download our infographic with the features of both systems to help you decide if single anchor points or a horizontal lifeline are more suitable for your project.