Fall protection comes in many forms and shapes. The key to choosing the right system is to determine what solution fits the demands of the client and the situation in which the fall protection is installed. Factors that play a role are whether a certain solution can be installed on the surface, the type of work that will be performed while using the system and the amount of fall clearance that is available.

Types of systems

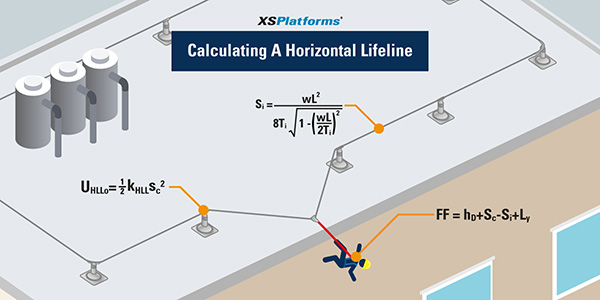

One of the solutions that is often applied on flat roofs, walls or on overhead structures is a trajectory of anchor points with wire rope tensioned between them. These are so-called horizontal lifeline systems or engineered systems. Workers are attached to the system by connecting their lanyard to a runner that slides along the wire rope and anchor points.

Another option to use on roofs, walls or overhead structures is a system that resembles a horizontal lifeline system: a rail system. This is a system that is connected to anchor points with a rigid rail. A specially designed runner slides along the rail to enable workers to walk along it while attached.

Although their functionality and appearance look the same, both systems have their advantages and features that fit a specific situation. In this blog, we will outline those features and describe in what situations which solution fits best.

Deflection

The amount of deflection of a system with wire rope is bigger than with a solid rail system. This has its advantages, but also disadvantages.

The advantage of little deflection (like with a rail system) is that the fall distance is shorter than with a lifeline system. So, when limited fall clearance is available in the projected situation, a rail system might be a good solution.

Integrating a system

When installed, the total height of a horizontal lifeline / engineered system on a roof is about 24 centimeters (9,5 inches). That of a rail system is approximately 15 centimeters (6 inches).

Overall, when installed on a roof, both systems aren’t visible from a lower level. But, when used overhead or on walls, the rail system can easily be integrated in the structure. When construction isn’t completed yet, the rails can even be fully integrated in the walls or ceiling. This way, the aesthetical value of a building is unaffected.

Fall protection can be integrated in a building’s design in the early stages of the design-process, using our 3D fall protection objects.

Replacement or repairs

Due to frequent use of a system or because of an arrested fall, a fall protection system can be damaged. A competent person must assess the system and order the damaged parts, or entire system, to be replaced.

In case of a lifeline / engineered system, when the wire rope or other components are damaged, it needs to be replaced. This can either be done by cutting the damaged part out and replacing it with a new piece of wire rope (by using a special connector that connects the old and new parts of wire rope, XTend for example). Another option is to replace the entire wire rope. Both options cost a fair amount of time. When a fall has occurred, not only the wire rope must be replaced, but also other parts of the system, like energy absorbers.

A rail system consists of rail pieces with fixed lengths of 2 to 6 meters (6.5 to 20 ft.). Replacing a damaged piece of rail is a matter of detaching the damaged part and replacing it by a new one. Compared to a engineered system, replacing a fixed length piece of rail after a arrested fall or damage is cost effective and less time consuming.

Harsh environments

Fall protection systems can be installed in many environments, ranging from business areas in cities, to industrial environments in or near harbors. Although all XSPlatforms fall protection systems are made of high-quality and long-lasting materials, they will be affected by dirty environments at some point.

Lifeline systems are less robust than rail systems and are affected by dirt and salt coming from the sea-air. They require more frequent maintenance when installed in a dirty, industrial environment.

Rail systems on the other hand are more robust. This doesn’t mean that regular maintenance isn’t required, but these systems are less affected by dirt and salt. Nevertheless, dirt always has to be removed before using the system, because otherwise the runner doesn’t run smoothly over the rails, affecting the user friendliness of the system.

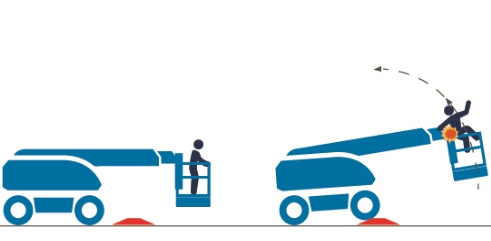

Rope access

In some cases, rope access is needed when a roof is steep or when a facade below the roof has to be accessed. For this, you can choose several anchor points to be installed: a single anchor point with a special RAP-globe, adding RAP anchor points to a lifeline system (like XSLinked) or a rail system with rope access runner.

Note: a special IRATA training is required for abseiling!

The RAP-globe and RAP enable rope access from one location on the roof. This could be sufficient for the given situation, but when a larger area needs to be covered, a rail system might be the better solution.

Rope access from the rail system is possible along the entire length of the rail and with a special abseil-runner with two attachment points (one for the main rope and another to attach a secondary safety line). To use the abseil runner, the worker needs to lock the abseil runner into the locking mechanism and descend down.

Costs of the systems

In general, a rail system is more expensive than a lifeline system, because of the solid, more durable materials that are used. So, when choosing one of both solutions, always assess the situation and determine whether the extra investment is worth it. For example, when a flat roof must be equipped with fall protection, a horizontal lifeline system is as safe and suitable as a rail system. So why would you invest more? A good reason might be that the building is located in a dirty environment and a there is a low fall clearance, making it unable to use a horizontal lifeline system.

In a nutshell: neither of the two solutions is better of safer than the other. The situation and demands determine what solution is the best choice.