After discussing the importance of using a personal energy absorber (PEA) and the role of the fall factor in a fall protection system, we will explain another important element when a fall protection solution is considered: fall clearance.

What is fall clearance?

Fall clearance is the minimum vertical distance needed between the worker’s feet and a lower level (this can be the ground level, but also a lower working platform for example) to prevent the worker from hitting the lower level in the event of a fall.

The calculated fall clearance of a specific fall protection system may never be equal or higher than the available clearance between the worker level and a lower platform. For example, if the fall clearance of a fall protection system is 6 meters (19,6 ft) and the distance from the working platform to the lower level is only 5 meters (16,4 ft), a worker will still hit solid ground when using that fall protection system.

That’s why a proper calculation of the fall clearance distance from the anchor point is very important!

How is fall clearance calculated for rigid anchor points?

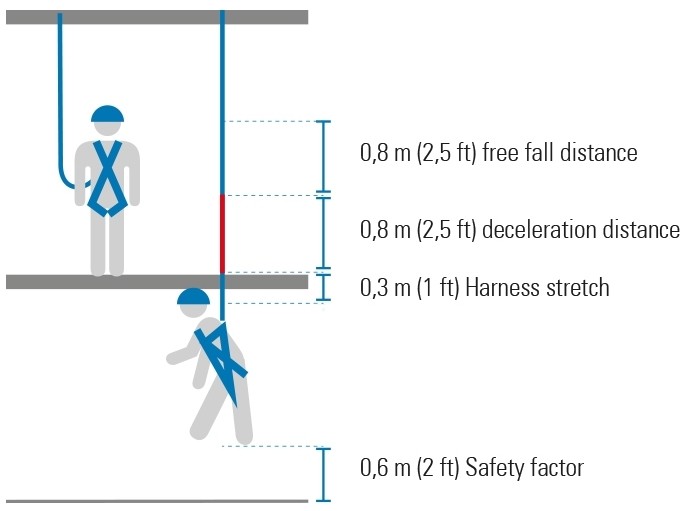

Fall clearance is calculated, based on multiple factors:

- Free fall distance

The distance, which you fall before the fall protection system begins to slow you down. According to OSHA standards, this distance should never be more than 1,8 meters (6 ft) and is based on the length of the lanyard and the location of the attachment point of the harness where the lanyard is attached to. Also, the placement of the anchor point and the activation distance of a fall arrester or a Self-Retractable Lanyard (SRL) play a role in this factor. - Arrest distance

The distance it takes for the personal energy absorber to activate and slow the fall. According to OSHA standards, this distance may not be bigger than 1,1 meter (3,5 ft). A personal energy absorber usually extends 0,8 meter (2,6 ft) in the event of a fall. - Harness stretch

When a user falls, the harness will stretch and the attachment point (D-ring or loop) is likely to shift. - Safety Factor

Additional distance to make sure there is enough clearance between the worker and the lower level. Typically measured as 0,6 meters (2,5 ft).

* The values given above are based on OSHA standards. Other applicable standards, specific situations or manufacturer details may deviate from these values.

So the formula to calculate fall clearance is:

Fall clearance = Free fall distance + Arrest distance + Harness stretch + Safety factor

Determining free fall distance

When the free fall distance is measured, multiple factors are taken into account:

- the placement of the anchor point;

- the vertical distance between the anchor and the lanyard’s attachment point on the full body harness.

The table below shows how the free fall distance is measured:

Calculating fall clearance

Now we will provide some basic examples of the calculation of fall clearance in three different situations.

Overhead anchor point

When a user falls from a ledge and while being attached to an overhead anchor point (1,2 meters/4 ft above the attachment point), using the dorsal D-ring on the harness and a 2 meter (6,5 ft) shock-absorbing lanyard, the needed fall clearance is as follows:

- Free fall distance = 0,8 meter (2,5 ft) (2 meters (6,5 ft) lanyard – 1,2 meter (4 ft) distance between D-ring and anchor point)

- PEA extension = 0,8 meter (2,5 ft)

- Harness stretch = 0,3 meter (1 ft) (or more, depending on the manufacturer)

- Safety factor = 0,6 meter (2 ft)

Adding the data above, will result in a required fall clearance of 0,8 + 0,8 + 0,3 + 0,6 = 2,5 meters (8,2 ft). In the event of a fall, this is the minimum clearance required to prevent the user from hitting the level below.

Anchor point at the same level as the attachment point

A user is using a fall protection system with a 2 meter (6,5 ft) lanyard with PEA, attached to an anchor point that is located at the same height as the dorsal D-ring (attachment point on the harness). The fall clearance needed for this system is:

- Free fall distance = 2 meters (6,5 ft) lanyard

- PEA extension = 0,8 meter (2,5 ft)

- Harness stretch = 0,3 meter (1 ft) (or more, depending on the manufacturer)

- Safety factor = 0,6 meter (2 ft)

A fall clearance of 3,7 meters (12,1 ft) is required when this fall protection system is used.

Anchor point below the attachment point

In this situation, an anchor point is placed at foot level of the user, while a 2 meter (6,5 ft) lanyard with PEA is used. This might be considered when a worker walks over a steel H-beam without the possibility of an overhead anchor point. The fall clearance needed to use this system is:

- Free fall distance = 3,2 meters (10,4 ft) (2 meters (6,5 ft) lanyard + 1,2 meter (4 ft) distance between D-ring and anchor point)

- Extension PEA = 0,8 meter (2,5 ft)

- Harness stretch = 0,3 meter (1 ft) (or more, depending on the manufacturer)

- Safety factor = 0,6 meter (2 ft)

In this case, the free fall distance is quite high with 3,2 meters (10,4 ft) and a fall clearance of 4,9 meters (16 ft) is needed.

According to the examples above, fall protection systems with an overhead anchor point require the least fall clearance. In case the required fall clearance is not enough to use the intended fall protection system, other solutions have to be considered: A Guardrail system might be placed, making changes to the fall protection system by using a retractable device or a fall restraint system, or moving the anchor point for example.

Lifelines and retractable devices

The examples given in this article only show basic examples, using a lanyard with personal energy absorber and a rigid anchor point. In many cases, the calculations for fall clearance are more complicated as more factors have to be taken into account.

For example, when a horizontal lifeline is used, the calculations must include the deflection of the system and the distance from the system to the roof edge as well.

Making these calculations manually, taking all factors, applied forces, safety standards and situation characteristics into account, can be hard and entails the risk of making miscalculations, with all its consequences.

Calculation tool for lifelines: ODIN

To prevent miscalculations and provide an easy way to make calculations when choosing for a horizontal lifeline system, XSPlatforms has developed an online calculation tool named ODIN. The only thing a user or fall protection expert has to do, is enter all characteristics of the chosen system and the situation characteristics. After hitting the button, the program will do all calculations automatically.

Next, ODIN will indicate if the given solution complies to all local standards and is safe to use. If so, it will provide all (technical) documents for the fall protection system. If the system is not approved by ODIN, changes need to be made and calculations need to be done again.

Download the leaflet with all information and added value of ODIN below.